News

ESST/VDZ Sugar Conference from 5 - 8 May in Vienna

The 8th ESST/VDZ Conference of the European Society for Sugar Technology (ESST) and the Association of German Sugar Technologists (VDZ) will start on May 5th.

Sugar technologists from all European sugar producing countries will be present and we are looking forward to exciting discussions, international exchange and presentations.

KEBO shows with individual chemical solutions, such as anti-scaling agents, defoamers, cleaning agents and additives as well as crystallization nuclei and aids, KEBO supports its customers by significantly reducing their energy consumption and CO2 balance.

Visit us at our booth (#23) and let us show you our latest developments. We look forward to seeing you!

A trusted brand since 1926

We, Keller & Bohacek GmbH & Co. KG, are a globally active company in the specialty chemicals industry. When it comes to operating production plants, our products and services ensure clean processes. Whether for the sugar and steel industries or for the production of ethanol, starch and yeast, the focus is on the development and production of chemical solutions for cleaning processes, water treatment and corrosion protection.

At this, KEBO stands for constant innovation and responsible action, and we contribute to the economic success of our customers with our products and services. We offer the solution for very individual challenges with a lot of commitment and personal advice.

Individually tailored solutions for perfect cleaning and effective protection against corrosion and deposits. A success story in research and development.

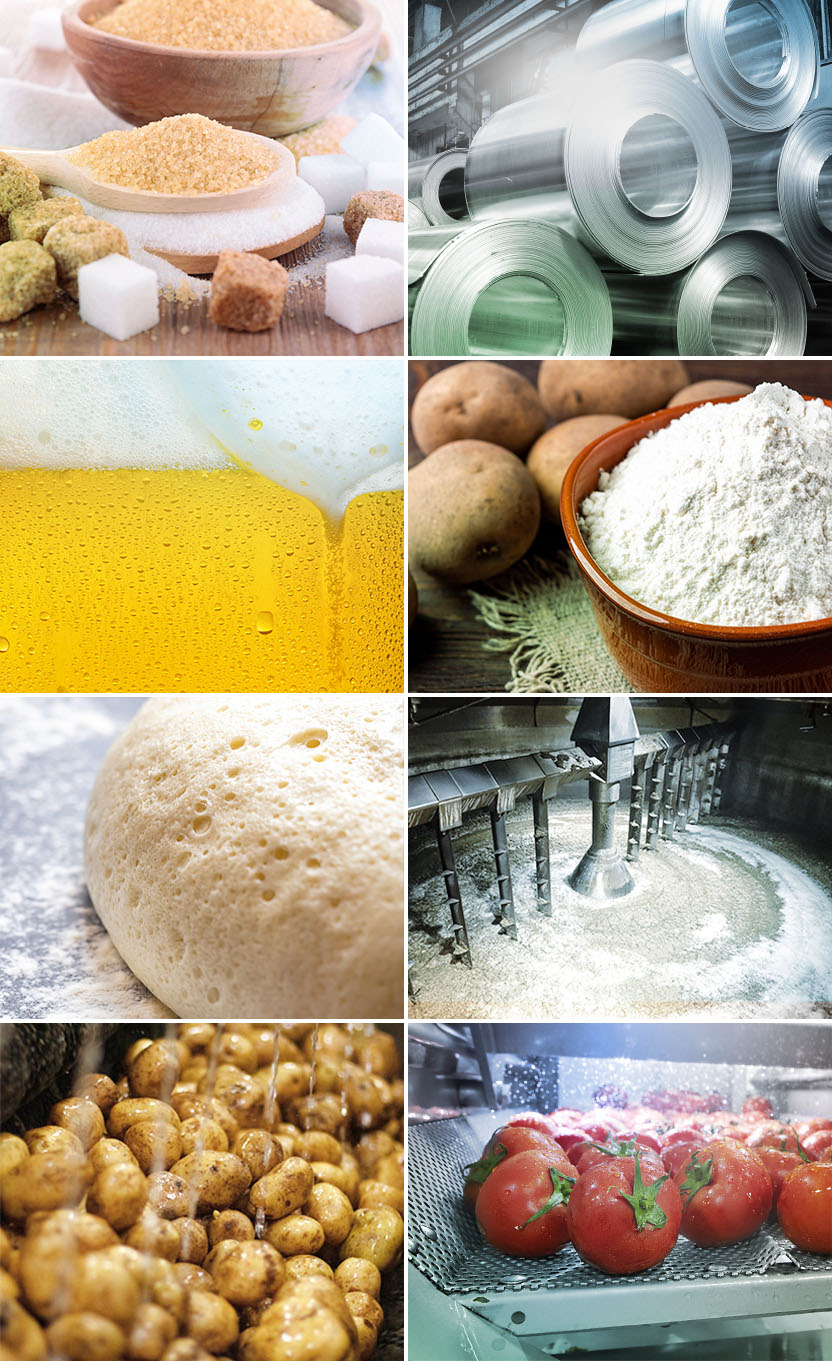

From food to steel: Individual service and customized specialty chemicals

Whether in the steel or food processing industry (such as in cane/beet sugar productions, in potato,corn, wheat-processing industries, fruit preparation, distilleries, fermentation, biogas plants, etc.), in power plants, refineries or the chemical industry - our personalized service is as responsive as our individual products. Because the interests of our customers are the focus of everything we do.

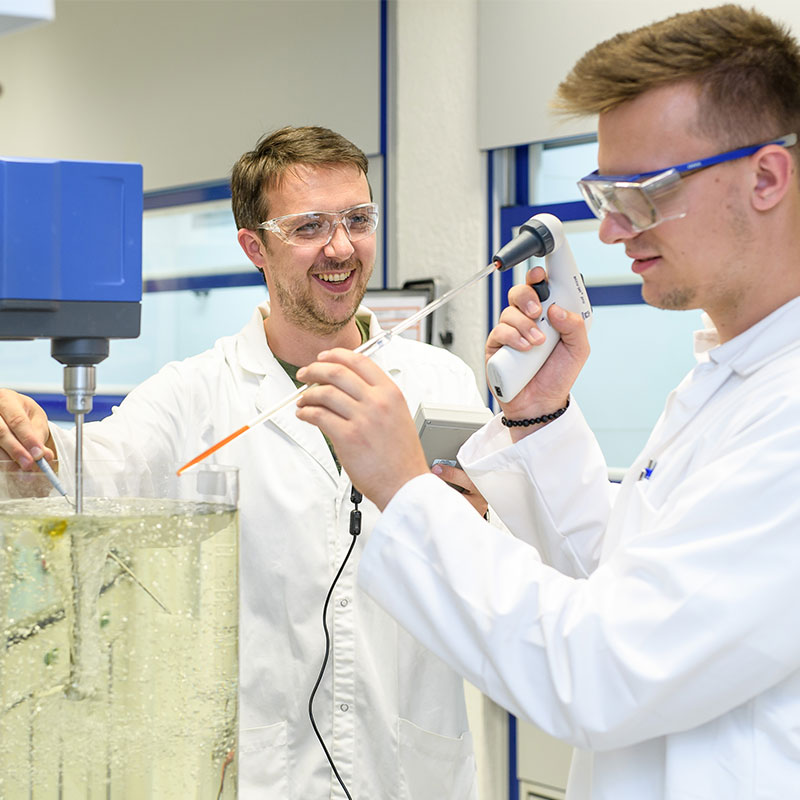

In our laboratories, we use state-of-the-art methods and procedures to analyze the exact composition of substances and substance mixtures in order to identify the tailor-made product from our specialty chemicals portfolio.

Always with the clear goal of extending equipment life, increasing quality and safety, and reducing maintenance costs.

We offer

- high and economical cleaning performance, thus saving on process costs

- increasing production safety

- increasing occupational safety

- ensuring the quality of your end product

- a reduced energy consumption (CO2 reduction)

Global expansion

From the very beginning, it was one idea (1926) above all that shaped our current corporate DNA. After all, anyone who deals with rust protection by nature is committed to maintaining the value and care of their customers' equipment. Over the years, this aspiration has not only given rise to considerable chemotechnical knowhow, but perhaps an even more important quality: the ability to listen. It is not by chance that KEBO sees itself today as a solution provider. And above all as a partner with special connections to its customers, with a great deal of commitment and personal consultation in solving very individual challenges. In 1926, Keller & Bohacek was founded as ""Rostschutz GmbH"" with a focus on the construction of galvanizing plants in Halle. At an early stage, our founder Dr. Alfred Keller, an engineer by passion, decided to enter the production of pickling inhibitors and thus laid the foundation for today's orientation as a specialized chemical company. Alfred Keller's daughter Renate joined the company in the 1950s as a chemist. From then on, she was the driving force behind the development of innovations and was regarded as the ""heart and soul"" of KEBO. Parallel to the development of products for chemical plants, steel industry and sugar factories, the field of cooling water and boiler feed water treatment was then worked on. The existing vast experience in corrosion protection as well as in scale prevention led to the development of effective water conditioners and scale inhibitors. Today, KEBO operates worldwide to meet present challenges on behalf of its customers.

.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.