Skilled treatment of boiler and feed water

Effective chemical pretreatment of boiler and feed water is critical to prevent boiler system corrosion and avoid deposits such as scale.

Our boiler water conditioning program allows customization to meet the specific requirements of your system. Our measures include alkalization according to the requirements of DIN EN 12953-10:2003, residual hardness binding to prevent scale formation, oxygen binding to prevent oxygen corrosion, and protection of the condensate system to prevent corrosion in steam generators.

- Alkalization: To avoid acid-related corrosion, boiler and feed water should be adjusted according to the requirements of DIN EN 12953-10:2003 (formerly TRD 611).

- Residual hardness bond: By a hardness dip in the event of malfunction of water treatment calcium (hardness) can be introduced. The product is able to bind calcium and thus prevents the formation of deposits. The bound hardness precipitates as sludge and is discharged via blowdown.

- Oxygen bonding: Oxygen bonding is essential in steam generators to prevent oxygen corrosion (oxidation). The product is able to bind free oxygen

- Protection of the condensate system if the dosage is sufficient: In steam generators, the steam can take on an acidic character due to the carbonic acid dissolved in the water, which can be expelled at the prevailing temperatures in the boiler. KEBOMIN S is partially vaporizable, provides an alkaline character of the steam and thus also of the condensate. Metallic materials in the condensate system are hereby protected against corrosion.

- Corrosion protection: In systems in contact with water, corrosion protection is important. Metallic materials generally behave corrosively in contact with water. The product helps to form a good magnetite layer in the water, which additionally protects the boiler from corrosion in the areas in contact with water.

- Food industry: In food processing plants, special requirements are placed on the treatment of boiler water. For this purpose, our products are optimized so that they do not pass through steam and remain completely in the water phase. In plants where the steam comes into direct contact with the food, these products can be used.

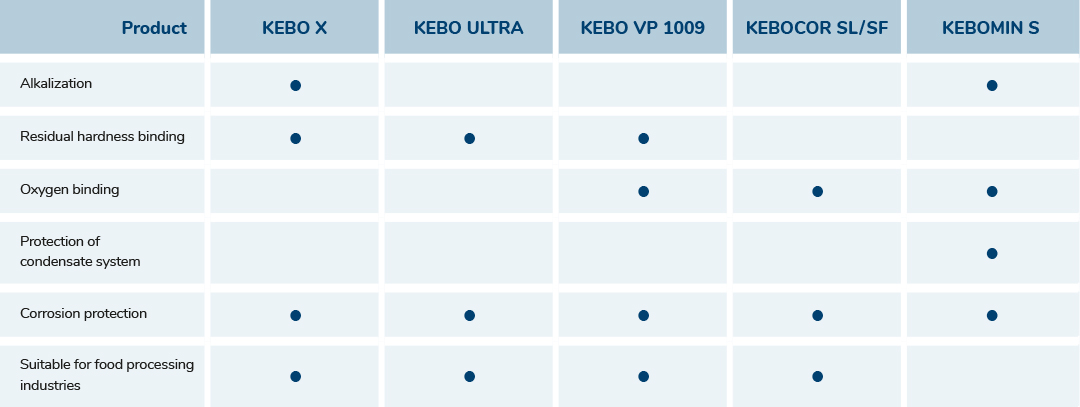

In the overview of our products for boiler and feed water:

With water analyses and on-site plant assessment, we develop the most economical conditioning proposal. Depending on the water quality and physical requirements, we adapt the product composition to the requirements of your plant.

Water treatment and conditioning in a steam and hot water boiler plant

Faulty water treatment and conditioning, inadequate water analytics and lack of water quality monitoring remain common causes of malfunction or damage in steam boiler plants.

Correct water treatment and conditioning is critical to ensure safe and long-lasting operation of steam boiler systems. To meet these demands, the water quality for steam boiler plants is subject to strict requirements. DIN EN 12953-10 stipulates compliance with defined water qualities for feed water and boiler water. Here are specific specifications regarding appearance, conductivity, pH, total hardness, acid capacity, as well as iron, copper, silica, oil/fat, phosphate and oxygen concentrations. In addition, the water should be free of organic substances.

These requirements for feed water and boiler water reduce or prevent potential damage and causes of faults such as corrosion, scaling, boiler water foam and sludge.

To ensure water quality and prevent damage from problematic constituents, appropriate water treatment and conditioning is required. Measures vary depending on boiler system capacity, condensate rate, and the constituents of the water.

The most commonly used terms regarding the different types of water are:

- Fresh water (raw water): This untreated water comes from various sources such as the public network, an own well or a spring. It serves to fill the plant and compensate for water losses.

- Additional water: This water, whether softened, partially desalinated or fully desalinated, is fed to the feed water tank for degassing.

- Feed water: The feed water for the boiler is softened, degassed and chemically conditioned. It is fed into the boiler via feed pumps.

- Condensate: This comes from closed vessels and is sent back into the feed water, as make-up water.

With pleasure, our experts are at your disposal to help you implement the right measures for water treatment and conditioning in your steam boiler plant. Contact us for a personalized consultation.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.